Post-harvest Management of Hemp Fiber

Post-harvest management of hemp grown for fiber depends on the ultimate destination of the fiber. Hemp contracted by textile industries has to be subjected to the retting process before the next handling step of raking and baling. If no retting is required, windrows of hemp stalks can be made in preparation for baling as soon as the straw is sufficiently dry (12-16 %).

Rotary rakes are recommended to handle hemp for both turning over stems during field retting process or forming windrows of dry straw in preparation for baling. Please note that the wheel rakes frequently used for hay management do not perform well with hemp since long tough stems easily wrap on the wheels making the windrowing process an inefficient task.

Depending on the processing plant equipment, both big round balers and large square balers could be used to handle retted or unretted material straw. Small square balers are not suggested as they frequently wrap fiber in the pickup.

Bales made using sisal twine are desirable; however, if plastic net wraps or twine are used they must be removed prior to processing. Bales have to be made to maximum size to help keep trucking costs down.

Retting of Hemp Fiber

Retting is a process in which pectineus substances that bind together elemental bast fibers become degraded. This progression is completed either by microorganisms present on the stems or in soil, acid/bases, or by special enzymes. Some call it a controlled rotting, which indicates that a farmer needs to oversee and properly manage the process.

While three major types of retting can be distinguished including field (or dew), water and chemical retting, Canadian hemp growers should be concerned only about the first type that can be done on a farm. Two other types require special facilities (tanks, dryers, specialty chemicals) and therefore are not included in this crop production guide.

Field retting is accomplished by leaving harvested hemp stalks on the ground for several weeks and relying on the weather to facilitate the process. Length of the retting process depends on availability of moisture and air temperature. Warm weather with intermittent precipitation maintaining moisture within the hemp stalks supports microbial activity and accelerates the process of pectin degradation.

To assure even and complete retting, the stems should be turned over when they start changing in color from green to pale yellow (Figure xix – PDF Below). Under optimal weather conditions, this stage can be reached two to three weeks after cutting. Turning over is recommended when hemp is meant for textile applications which demand high quality and uniformity of fibers and if the layer of hemp stalks are thick. Without turning stems over, the stems at the bottom, closer to the ground, could be easily over-retted and hence quality of both hurd and bast fiber would be compromised. While in Canada there is no specialized equipment available to do this task, rotary rakes could be used to avoid loss of fiber yield and quality.

Retting is completed when microbes decompose pectin binding fibers and stems turn color to medium–dark beige with small dark, moldy spots (stage 6-8 in Figure xix – PDF Below). Hurd and bast fibers in properly retted stems separate easily at breaking and bast fibers form characteristic bands.

In some Prairie regions frequently receiving miniscule amounts of rain in August and September, retting could take a long time and sometimes may not be completed before winter. In such cases, the stems could be left on the ground until the following spring for baling in May. Fiber from winter-retted stems is suitable for biocomposite applications; however, for high end textile applications, leaving the stems on the ground may lead to over-retting which weakens fiber strength and reduces its quality. To assure optimal retting conditions, hemp stalks meant for textile applications may be wetted with a few inches of water to support microbial activity. Such management practice could be implemented in the irrigation districts

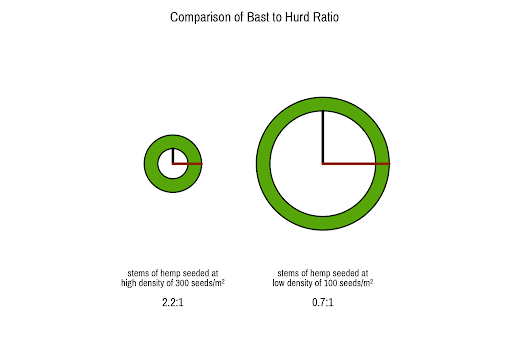

Stems of cv. Silesia seeded at 110 lbs/acre (left) and 33 lbs/acre (right)

Owed to their different physical properties and chemical composition, bast and hurd fibers are suitable for a wide range of industrial applications including bio-composites, construction materials, textiles, insulation, bedding, paper production, ropes and twines and many others.

Until recently, major breeding efforts of the fiber usage type varieties were focused on increasing bast fiber content of the stem, mainly for textile industries. Revival of hemp production during the last decade resulted in developing applications for hurd as well, with building products being one of the chief materials driving hemp for fiber expansion. Biofeedstock needs for eco-friendly composites and plastics will further increase hemp fiber demand.